Improves services through technology to

become the best gearbox operation and

maintenance enterprise in the world

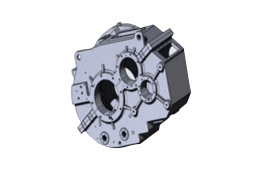

Gearbox designing is to ensure that each interface of the gearbox matches that of the original gearbox and then re-designing the gearbox (including gearbox structure, gear parameters, gearbox lubricant oil ways, etc.) allows the gearbox have a more reasonable structure, better gear strength, and more suitable lubrication. This is better suited for up-tower services.

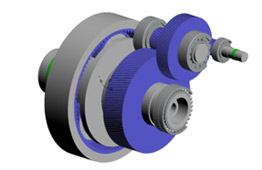

On the premise of ensuring the reliability, design and adjustments of the gearbox housing structure, gear shafts, and gear space layout to realize the replacement of parallel stage shaft systems in up-towers only using related process equipment. This significantly reduces maintenance costs for faulty gearboxes.

Advantage:

Greatly reducing the cost of operation and maintenance, making the gear box easy to maintain.

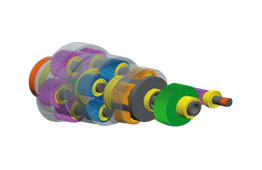

adjusting or re-designing gear parameters to further improve the gear's anti-scuffing capacity, contact strength between gear and tooth face, dedendum bending strength, and other performance indicators. This makes gearbox operations more reliable.

Advantage:

Making the gearbox running more reliable.

Calculating the best parameter values (such as bearing clearance, bearing stiffness, bearing stress, etc.) of bearing performance by using special bearing software plus AVISTT's experience on bearing configuration to design, optimize or re-design gearbox bearings to extend bearing service life. This improves bearing reliability and reduces costs.

Advantage:

Improve the reliability of bearings and reduce the cost of bearings.

On the premise of ensuring the lubrication of all bearings and gears, re-designing or adjusting oil tube ways to make oil distribution at each lubricating point more reasonable. This extends the service lives of gears and bearings.

Advantage:

Can improve the gear and bearing life.

AVISTT has successfully optimized the designs for four models among the 660 KW, 850 KW, 1.5 MW and 2.0 MW series. The design contents include the housing structure, gear parameters, bearing configuration, and lubricant oil ways.

After optimization, gearbox gear stiffness has been improved. In addition, all parallel stage shafting can be replaced up-tower, and even the sun gear can be replaced up-tower.

On the premise of ensuring that each interface size of the new gearbox matches that of the original gearbox, integrate advanced gearbox design to new gearboxes according to industry standards.

Change and design local structures, lubricant oil ways, gear parameters, and bearing parameters of the original gearbox without changing the interface size of the original gearbox.